Multi-outlet bin activator

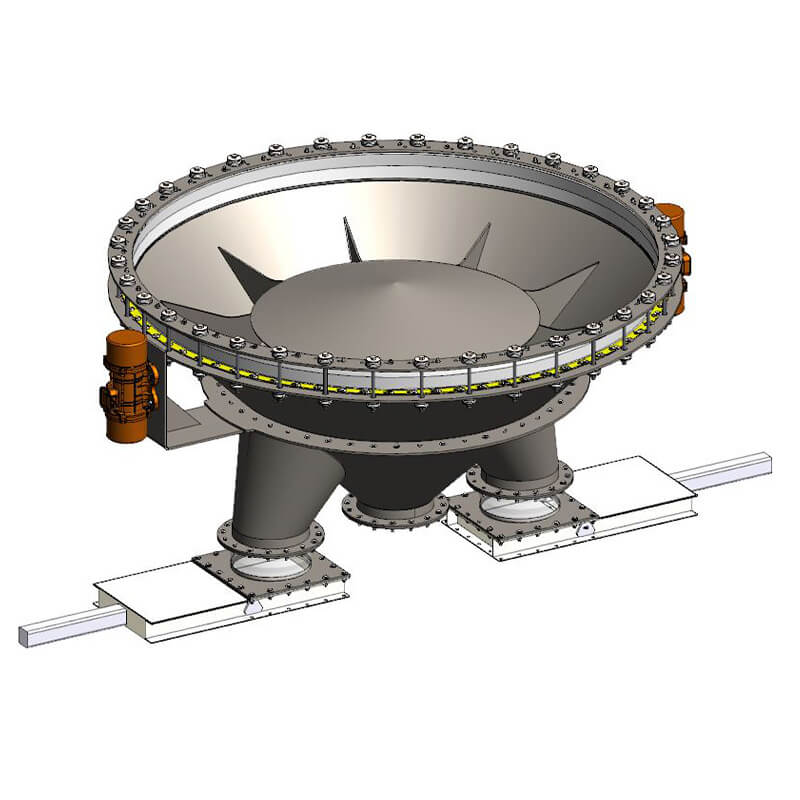

Multi-outlet bin activator

The bin activator is placed under the silo, it allows the extraction of powders with the difficult flow, by a vibration system. This action does not require human intervention.

In addition to its standard range, ISERCO offers special bin activators, adapted to the production needs. The multi-outlet bin activator is one of the equipment designed to meet a specific demand. It is used in cases where it is necessary to bring the product to several parts of the production process. This type of bin activator also helps to increase the extraction rate of the powder contained in the silo.

According to the size of the bin activator and the feeding requirements, it is possible to produce a bin activator with up to five outlets.

The multi-outlet bin activator has many benefits:

- It ensures a regular extraction

- The emptying is generated automatically

- It allows optimizing the production by increasing the flow of extracted product

- It consumes less energy per extracted ton

- It is silent

- Its maintenance cost is negligible

Our bin activators are made of carbon steel or stainless steel.