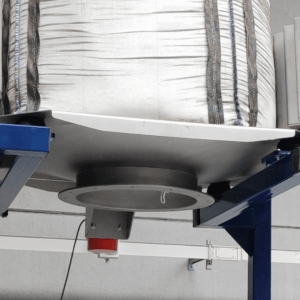

Description

The big bag emptying stations allow a safe and effortless deconditioning of powders. ISERCO determines with its customers, the best options to be applied according to the characteristics of the product and the process adopted by the customer. This is in order to obtain optimal extraction of the powders contained in a big bag, whatever the conditions in which the storage is carried out.

The benefits of our big bag emptying stations:

- They do not present any risk for the user

- They are ergonomic

- They adapt to all big bag sizes

- They are delivered custom-made and adapted to each production process

- They are inexpensive and their maintenance cost is negligible

If you wish, our engineering department can carry out a 3D scan on site to design an emptying station that fits perfectly into your plant.