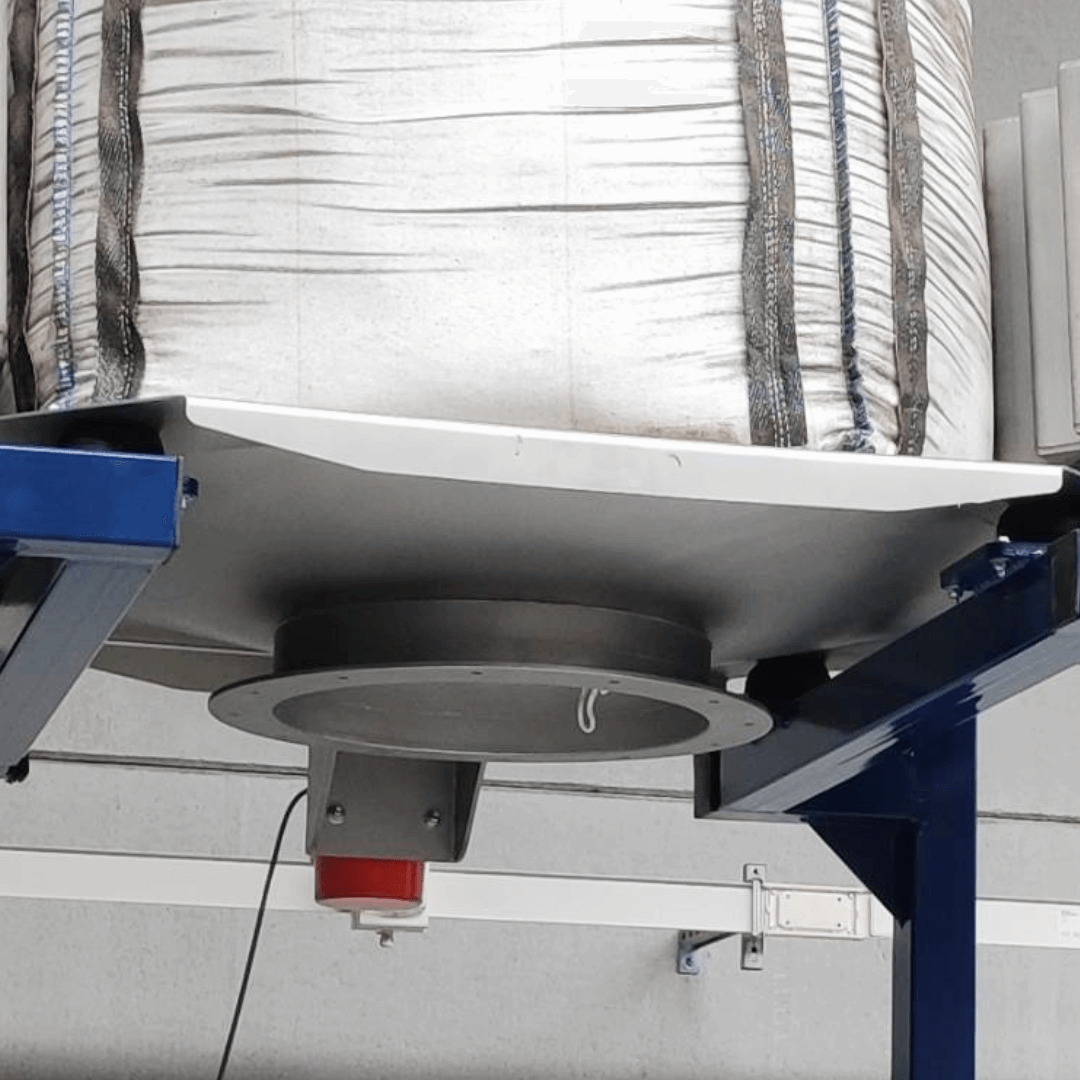

Vibrated hopper

Vibrated hopper

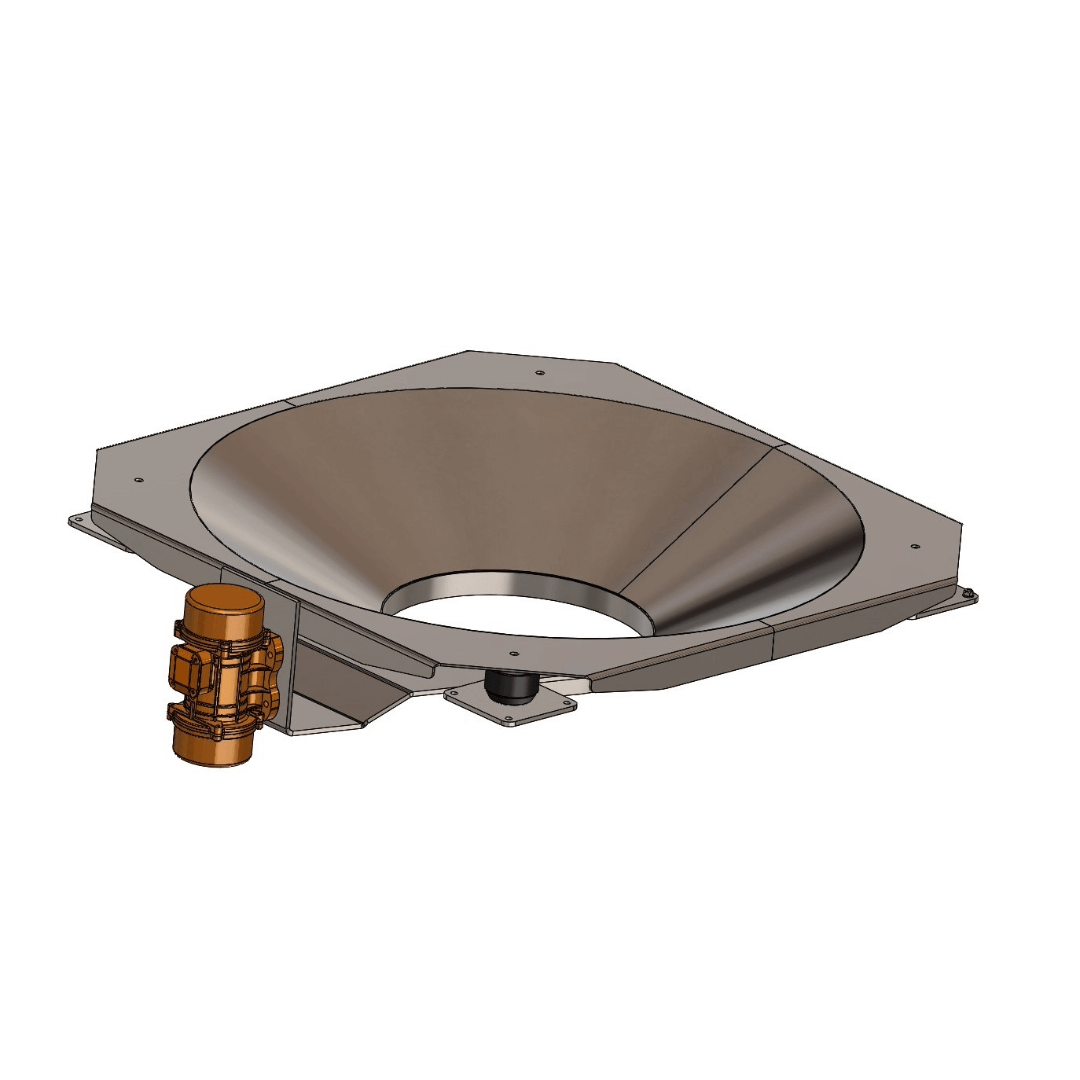

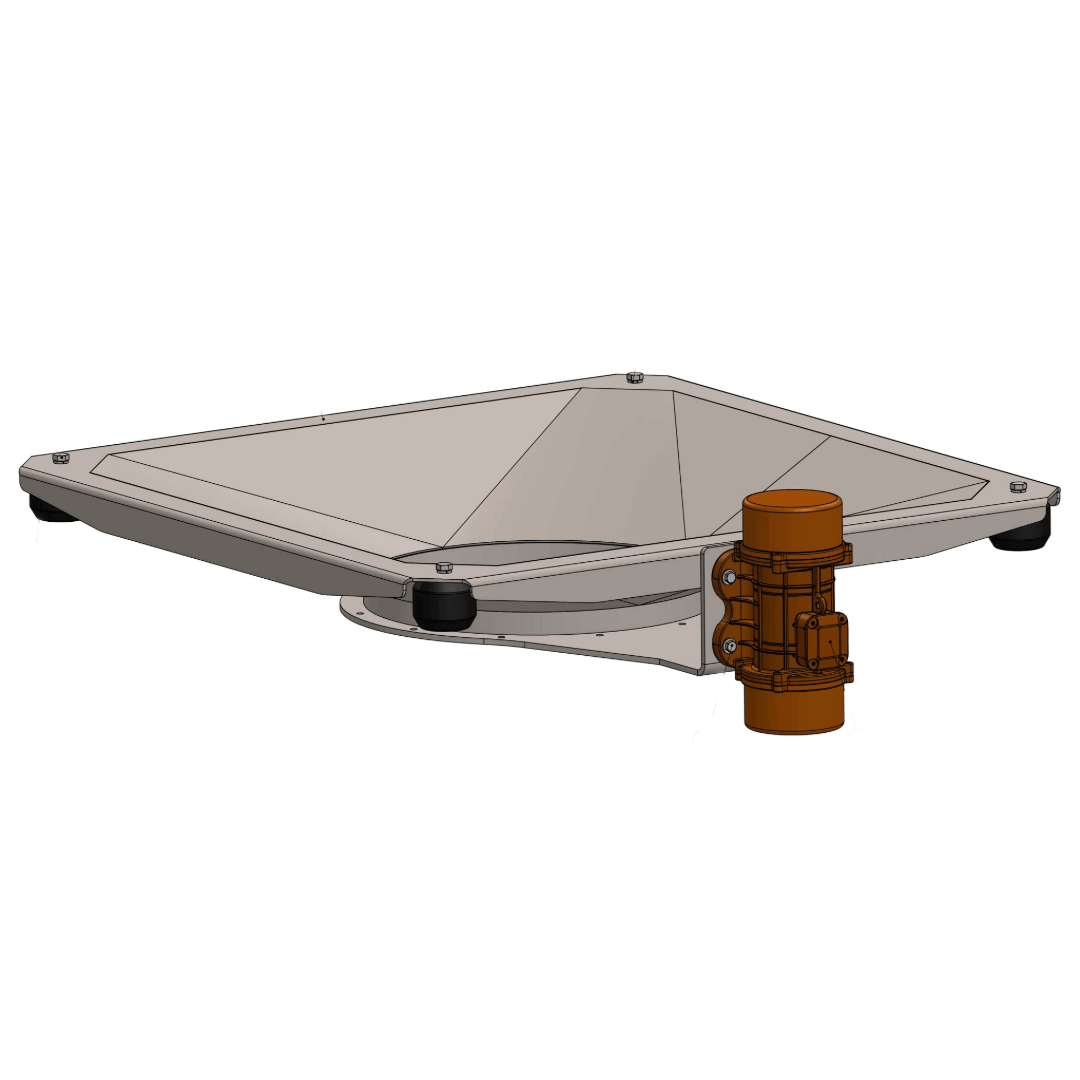

Round or square in shape, the vibrating hopper is a component associated with the bag emptier. It is used for emptying products stored in big bags, which have settled during transport and/or have little natural flow. It is activated by one or two vibrating motors and rests on 4 silentblocks. The purpose of the silent blocks is to absorb the vibrations of the moving hopper.

The vibrating hopper is generally combined with an unloading box. This allows the operator to open the laces of the big bag in a ‘closed’, cleaner environment.

It can be made of carbon steel or stainless steel.