Filling station filling rate ++ (up to 30 big bags per hour)

Filling station filling rate ++ (up to 30 big bags per hour)

ISERCO offers a wide range of big bag filling stations to meet the needs of the industrial world.

ISERCO develops ergonomic and customized filling stations to meet the specific needs of flexible container users.

A Big Bag filling station offers benefits such as:

- regular and controlled filling

- the absence of risks and it is ergonomic for the user

- Adaptation to several sizes and types of Big Bags (FIBC, FIBS, super sack, jumbo bag, bulk bag, bag)

- Optimization of the company’s productivity

- A low price and a negligible maintenance cost

Our big bag filling stations are custom designed and adapted to each production process.

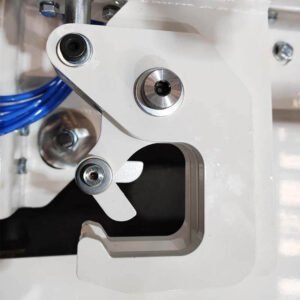

For a filling station capable of filling up to 30 big bags per hour, it is advisable to opt for a station operating with a semi-automatic mode. A semi-automatic station requires minimal handling by the operator. The operator simply puts the big bag in place at the filling head. After this action, the operator can launch the big bag filling cycle automatically. For this purpose, we integrate a PLC program that interacts with level probes or scales. The flow rate is adjusted by automatically opening and closing a feed valve. A semi-automatic station is also capable of interacting with the weight set by the operator. Once this weight is reached, the filling process stops.

A semi-automatic filling station also has a safety system that stops the machine in case of an anomaly detected by the PLC program.